Grease traps play a vital role in maintaining the efficiency, cleanliness, and compliance of commercial kitchens. Without proper grease trap maintenance, food establishments risk facing costly plumbing issues, violations of local plumbing codes, and environmental damage from grease entering the public sewer system.

This comprehensive guide to commercial kitchen grease trap guidelines explains how grease traps work, the types of grease traps, proper sizing, installation, cleaning schedules, and how to stay compliant with local regulations.

What Is a Grease Trap?

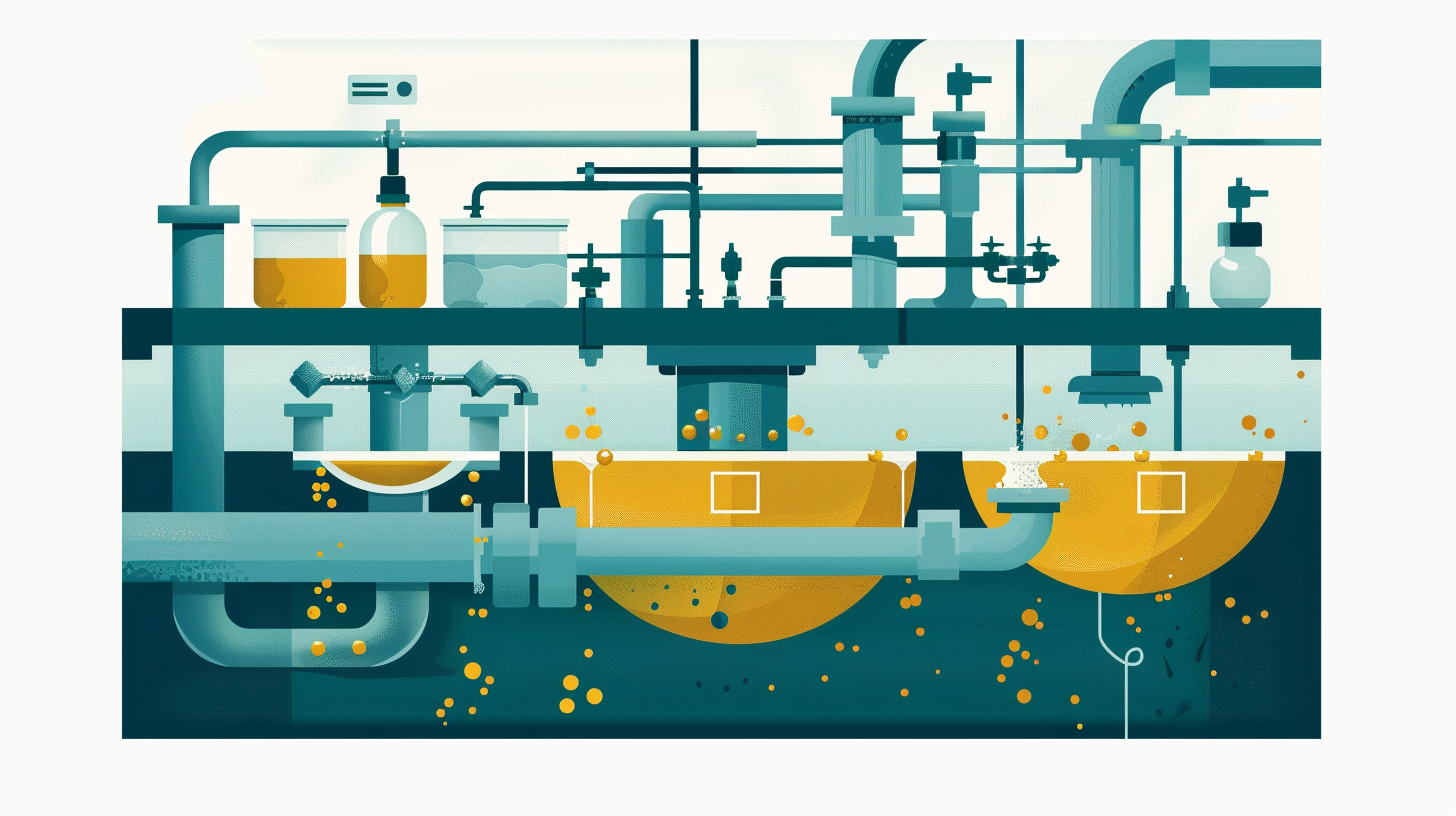

A grease trap is a plumbing device designed to intercept fats, oils, and grease (FOG), along with food waste, before they enter the sewer system. Grease traps are typically installed in commercial kitchens under sinks or in drainage systems to prevent these materials from reaching municipal sewer systems.

When hot wastewater enters the trap, the incoming flow refers to water mixed with fats, oils, and grease from activities like washing dishes.

Inside the trap:

-

Fats, oils, and grease float to the top

-

Food waste and solids sink to the bottom

-

Cleaner water exits via the outlet pipe into the sewage system

This setup protects the plumbing system and ensures the entire operation runs efficiently.

Why Commercial Kitchens Need Grease Traps

All commercial kitchens are required to install grease traps or grease interceptors under local plumbing codes and health standards. A properly maintained system helps:

-

Prevent grease buildup in sewer lines

-

Avoid costly plumbing issues and recurring maintenance costs

-

Eliminate foul odors and unpleasant odors from food prep areas

-

Stay compliant with local laws and health inspectors’ requirements

-

Protect the public sewer system from contamination

Without proper maintenance, businesses risk fines, closures, and damage to the plumbing system.

Types of Grease Traps

There are multiple types of grease traps to meet the unique needs of each food establishment:

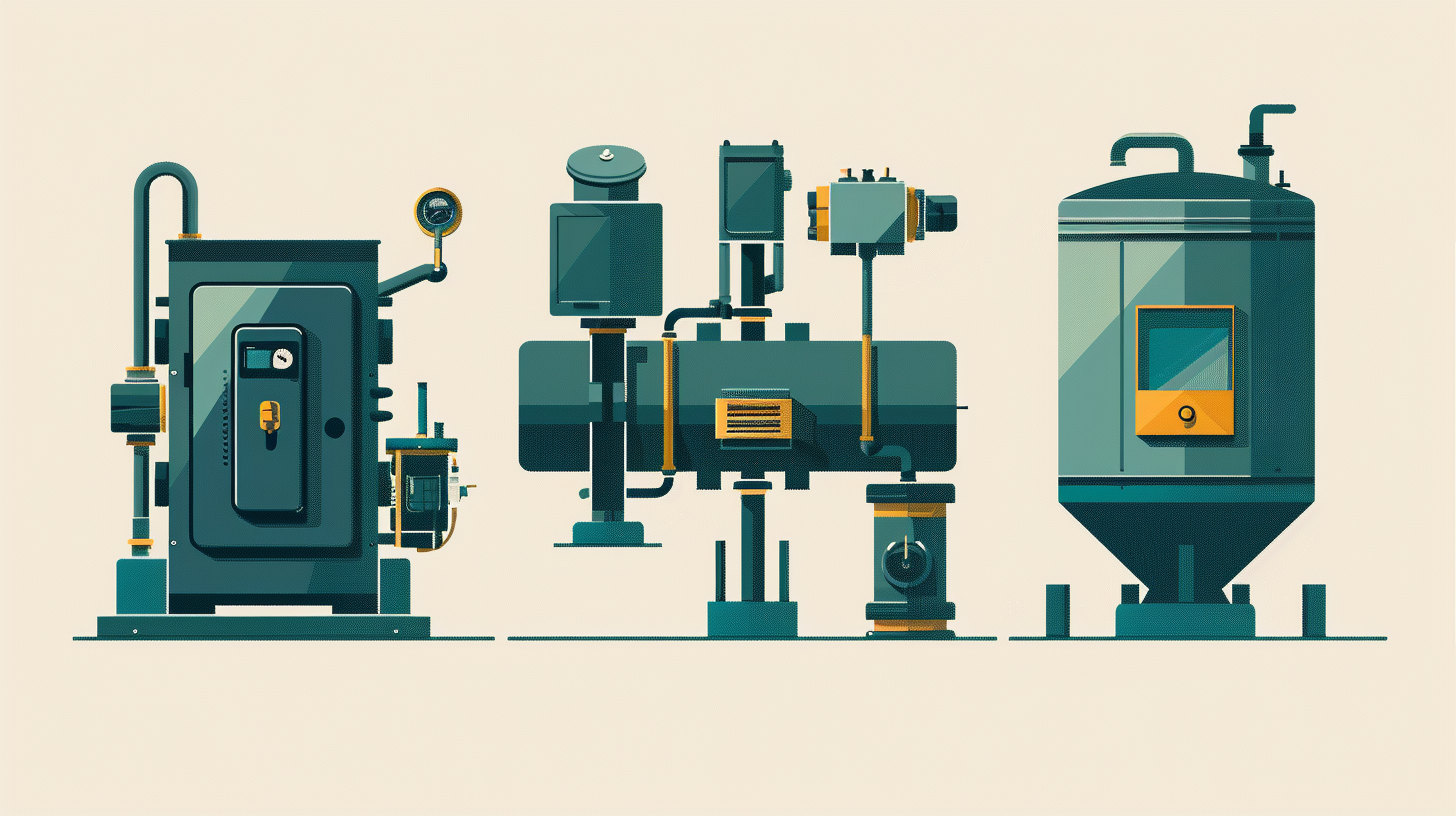

Manual Grease Traps (Passive Grease Traps)

Also known as passive grease traps, these are typically installed under sinks and are ideal for small kitchens. They require frequent manual cleaning.

Gravity Grease Traps

Gravity grease traps are larger, outdoor units built for commercial kitchens that generate higher grease output. These handle greater flow rate and larger grease trap size needs.

Automatic Grease Removal Units (AGRUs)

Automatic grease removal units continuously skim grease into external containers. These reduce labor, improve efficient operation, and support high-volume establishments.

How Grease Traps Work

As hot wastewater flows through the plumbing system, the grease trap separates fats, oils, and grease before they reach sewer systems. The incoming flow from sinks, dishwashers, and drains slows, allowing grease to float and food waste to settle. Clean water exits to the municipal sewer system.

Proper grease trap function is vital for effective grease management and maintaining a clean, efficient kitchen.

Determining the Right Size Grease Trap

Selecting the right size grease trap ensures effective performance. The grease trap size should account for:

-

The number of sinks and commercial dishwashers

-

Maximum flow rate in gallons per minute

-

Volume of fats, oils, and grease generated

The size of the grease trap is typically measured in gallons. Following standards by the Plumbing and Drainage Institute (PDI)ensures compliance. Always consult a professional plumber for sizing and installation guidance.

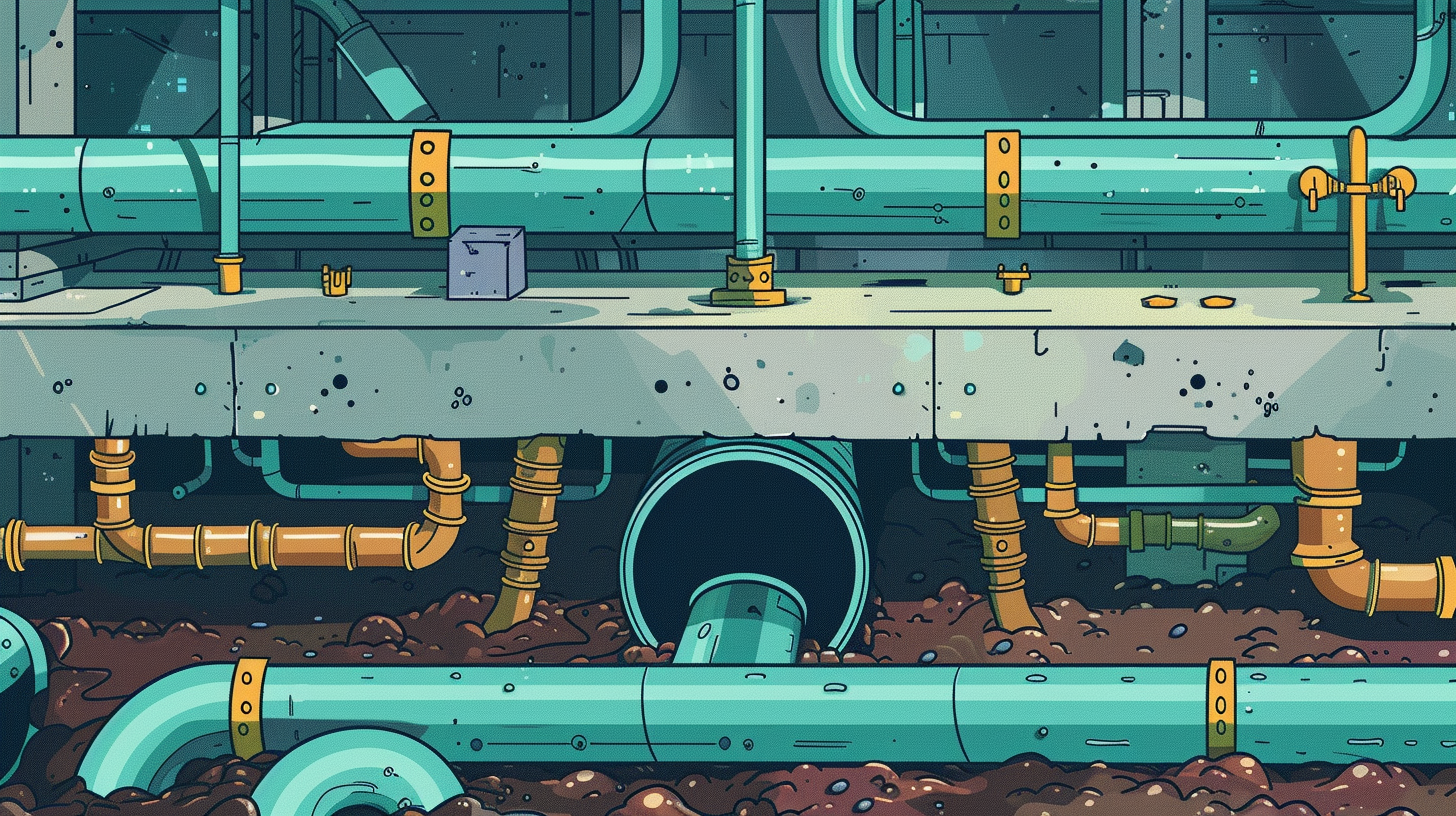

Where to Install a Grease Trap

A grease trap is typically installed:

-

Under sinks or near floor drains

-

Between kitchen plumbing and the wastewater system

-

Outside for larger gravity grease traps or grease interceptors

Correct placement ensures grease traps collect grease effectively and prevent clogs within sewer systems.

Grease Trap Cleaning and Maintenance

Grease trap cleaning and inspection are vital for proper maintenance. Regular servicing includes:

-

Scheduled pumping and removal

-

Checking the outlet pipe and seals

-

Monitoring for foul odors or slow drainage

-

Maintaining cleaning logs for health inspectors

Working with certified providers like Eazy Grease ensures waste is properly handled and documented per local regulations.

Common Issues with Grease Traps

Neglected grease traps lead to:

-

Blocked sewer lines and plumbing issues

-

Overflow near floor drains

-

High maintenance costs

-

Non-compliance with local plumbing codes

Early detection and cleaning prevent downtime and protect your entire operation.

Compliance and Local Regulations

Every food establishment must comply with local plumbing codes and local regulations regarding grease management. This includes maintaining logs, following grease trap size requirements, and ensuring all waste is properly disposed of.

Non-compliance can result in violations from health inspectors, so it’s essential to schedule regular cleaning with certified professionals.

The Role of the Plumbing and Drainage Institute

The Plumbing and Drainage Institute sets standards for grease traps based on flow rate, grease trap size, and design. Their guidelines help ensure proper sizing, installation, and compliance with plumbing codes across the U.S.

Key Takeaways

-

Every commercial kitchen must use a grease trap or grease interceptor

-

Use the right size grease trap based on flow rate and kitchen output

-

Schedule regular grease trap cleaning for compliance

-

Follow local regulations and PDI standards

-

Partner with Eazy Grease for professional grease management and maintenance

Find out if you qualify for Grease Trap Cleaning Service with Eazy Grease. Contact us to find out more.